Bholster Technologies provide support for die casting, permanent mold and sand casting. We are ideally suited to support small and mid-size casting operations on a continual basis while our cutting edge science of casting has supported the automotive sector on successfully casting very large thin-walled structural parts.

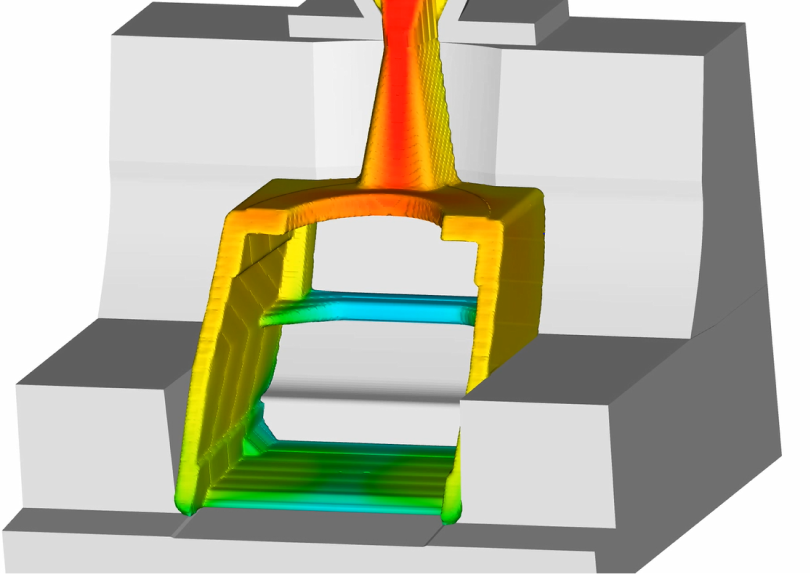

Success in casting programs comes from effective up-front design of gating, cooling and venting. This is achieved by using simulations to validate and optimize designs.

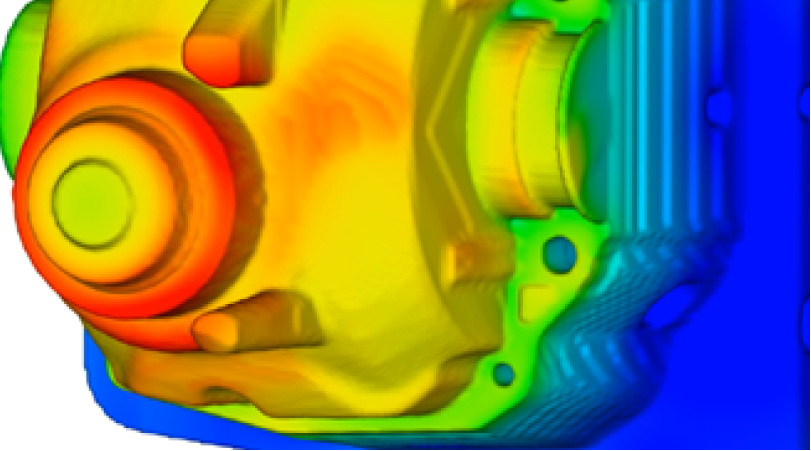

By combining the use of advanced CFD technology that accurately accounts for the physics of free surface flow and heat transfer with carefully researched and measured inputs for specific casting processes we have a methodology that converges on the actual cause of casting defects and provides dependable solutions

Bholster Technologies will help you to avoid expensive trial and error processes on real prototypes. We provide a cutting edge expertise without any overhead cost that is typically involved. We provide flow and thermal simulations at an affordable flat rate. You will get cutting edge expertise without any overhead cost that is typically involved.

At Bholster Technologies we empower foundries to effectively design and optimize their casting operations. Our service can help avoid costly trial and error and design rework and loss of productivity.

We work closely with our clients and deliver the complete cooling, gating, overflows and riser design in 3D CAD format.

The laws of Physics literally determine the outcome of most events in the universe. A simple example is Newton’s law of motion (Published in 1687) is all that is needed to predict the path of the Voyager spacecraft through our planetary system. In fact, the path of Voyager was predetermined and plotted well before anything was built so that engineers can be sure of what will happen. The act of predicting and plotting of the path ahead of time is a simulation.

Multiphysics simulation is simply accounting for the combined effects of more than one of the laws of physics to predict what will happen ahead of time. We have brought die casting down to a science. We did this by identifying all of the dominant Physics that govern the process and develop a solid and crystal clear applications of these laws to know exactly how things will work.